Product Information

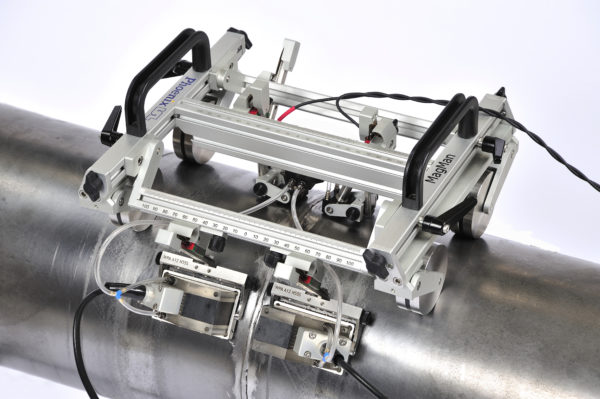

MagMan can hold twelve probes, so is ideal for inspections requiring a combination of phased array and one or more TOFD pairs or multiple UT probes and can be configured to inspect pipe welds from 2” OD circumferential and 9” OD longitudinal up to flat on ferromagnetic material.

MagMan updates include, Three new increment rails for more accurate PCS measurements, A waterproof spring-loaded wheel encoder and Quick release toolpost and wheel adjustments and quick release wedge changes, reducing the reliance on tools.

Compact yet robust, MagMan also benefits from large magnetic wheels providing a stable platform and a smooth rolling motion. The frame includes angular adjustment to enable the scanner to be used on small diameter pipes.

Up to twelve transducers, arranged as six pairs on either side of the weld are mounted on to spring-loaded toolposts that push them onto the inspection surface with a constant force providing a stable positioning system. The toolposts incorporate gimbals in two directions to ensure the transducers stay in constant contact and accommodate surface variations.

MagMan can operate with any multi-channel flaw detection system and optional accessories include, a guide chain to maintain scanner alignment and direction or a laser guide for the operator to track a weld line by eye.

Benefits:

- Versatile solution holding up to 12 probe combinations of phased array, TOFD and conventional UT

- Adaptable scanner covers from 2” OD circ and 9” OD seam welds, up to flat

- User-friendly quick release adjustments for ease of use in the field

- Accurate PCS measurement using new increment rails

- Customisable with a wide range of accessories or for bespoke applications

- Robust construction for site conditions

- Compatible with any manufacturers probes, wedges and flaw detectors

Specification:

- Holds from 2 up to 12 probes

- Quick release adjustments throughout

- Frame incorporates three measurement rules for accurate probe separation

- Probes independently sprung and gimballed

- Independent suspension on all 4 magnetic wheels for uneven surfaces

- Accurate tracking via guide chain or laser

- Water-proof, spring-loaded wheel encoder

- Compact design: 350mm x 325mm

- Lightweight yet robust aluminium frame: 3kg

Standard Kit:

- 1 x Adjustable scanner frame

- 4 x Magnetic wheeled suspension units

- Waterproof spring-loaded encoder wired for any system (includes 5m cable)

- Standard Tool-posts (see order information for quantities and codes)

- 2 x Phased array wedge cradles (applicable to PA models only)

- Irrigation manifold and tubing

- 1 x Rugged hand carry case

Options and Accessories:

- AEP-TPOST-30 Standard Toolpost

- AEP-TP-FORKS-30 Forks & 30x30mm base

- AEP-TP-PA-CRADLE Phased Array Cradle

- AEP-ENCWP-2.5M-TERM Wheel Encoder with 2.5M cable

- AEP-ENCWP-5M-TERM Wheel Encoder with 5M cable

- AEP-MAGMAN-ENC-BRACKET Encoder Bracket

- AEP-MAN-CHAIN 5M Guiding Chain

- AEP-MAN-CHAIN-GUIDE Chain Guide Bracket

- AEP-MAGMAN-PCS-EXT-BAR Bar attachment

- AEP-MAN-LASER-GUIDE Laser guide and bracket