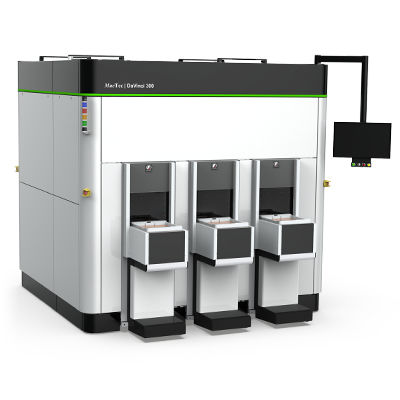

HRD-45C test process is automatic, and no one is responsible for reading error. The accuracy shall comply with GB / t230 2 ISO 6508-2 and ASTM E18. Application scope: Rockwell hardness measurement of ferrous metals, non-ferrous metals and non-metallic materials, It is suitable for Rockwell hardness measurement of quenching, quenching and tempering and other heat treatment materials, Surface Rockwell measurement of ferrous metals, alloy steel, cemented carbide and metal after surface treatment (carburization, oxidation Surface Rockwell hardness of electrodeposited coating, It is especially suitable for precise measurement of parallel planes. Main technical specifications: Measurement range: 20-88hra, 20-100hrb, 20-70hrc, 70-94HR15N,42-86 HR30N,20-77 HR45N, 60-93 HR15T,29-82 HR30T,10-72 HR45T Test force: 588.4980.71471n, (60100150kgf) 147.1,294.2,441.3N,(15,30,45kgf) Maximum allowable height of sample: 210mm, Distance from indenter center to machine wall: 165mm, Hardness resolution: 0.5hr, Overall dimension: 522x293x729mm, Weight: about 98kg Standard configuration: large flat test bench: 1 small flat test bench: 1 V-shaped test bench: 1 diamond indenter: 1 1 / 16 ‘steel ball indenter: 1 surface Rockwell hardness block: 4 Rockwell hardness blocks: 5

Технические характеристики

CharacteristicsTypeRockwellMountingbenchtopOther characteristicsautomaticLoad

Min.: 15 kgf

Max.: 150 kgf

Weight

98 kg (216.1 lb)