Description

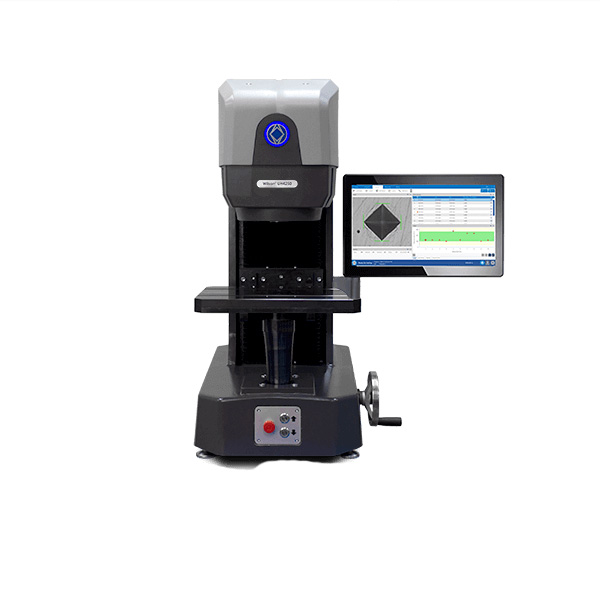

The Wilson UH4000 series universal hardness tester is designed for high volume production labs and production floor environments. As a Universal hardness tester, the UH4000 series can perform several different hardness scales in one machine including Vickers, Knoop, Brinell and Rockwell, in most cases at higher loads (>,5 kgf). Tests are carried out via its DiaMet software, the most intuitive hardness control software on the market, ensuring easy and repeatable, automatic testing.

Wide Range of Test Loads

The UH4000 series is available in two different configurations — the UH4250 and UH4750. The UH4250 features test loads of 0.5-250 kgf, and the UH4750 has a broader range on the high-end going from 3-750 kgf. Both the UH4250 and UH4750 are sturdy, reliable machines and suitable for demanding and rough workshop environments.

Fast Testing Cycles & No Manual Indenter Changes

The UH4000 series testers offer rapid testing cycles and a newly designed turret that holds several indenters and objectives. These series of testers eliminate the need for manual indenter/objective changes when using a variety of testing methods.

Sturdy & Designed for Heavy/Big Parts

All of the UH4000 testers are made from a very robust and sturdy Aluminum alloy, including the turret cover, which protects the highly accurate hardness measurement system and turret assembly from damage or external influences. Each tester can test heavy and big parts due to its large T-slot stage (300mm [11.8in] x 400mm [15.7in]) and the weight capacity.

Applications

Wilson has designed the UH4000 series to be well suited for the following applications:

- Broad testing across automotive and aerospace industries

- Hardness of castings and forgings

- Flat and cylindrical workpieces

- Product quality control testing

- Steels, non-ferrous metals, stainless steels, heat treated materials

- Cemented carbides, ceramics

- Plastics and carbon testing

Технические характеристики

Specs

| TESTER | UH4250 | UH4750 |

| HARDNESS SCALES | HV 0.5 — HB 10/250 | HV 3 — HBW 10/750 |

| TEST LOAD RANGE | 0.5-250 kgf | 3-750 kgf |

| TEST LOAD TYPE | Closed loop | |

| OPTICS | 5-megapixel USB 3 digital camera, with digital zoom and autofocus | |

| TURRET | 8 positions for objectives and indenters | |

| OBJECTIVES LONG | 2.5x (optional with ring light) | |

| WORKING DISTANCE (OPTIONAL) | 5x | |

| INDENTERS (OPTIONAL) | Brinell 1mm, 2.5mm, 5mm and 10mm carbide balls Rockwell diamond cone, 1/16, 1/8, ¼,, ½, carbide ball indenters Vickers diamond Knoop diamond | |

| OPTICAL MEASUREMENT | Manual or Auto-measurement of indent images | |

| BRINELL TEST PROCEDURES ISO 6506-1, ASTM E10 | HB1: 1, 2.5, 5, 10, 30 HB2.5: 6.25, 15.625, 31.25, 62.5, 187.5 HB5: 25, 62.5, 125, 250, 750* HB10: 100, 250, 500* | |

| VICKERS TEST PROCEDURES ISO 6507-1, ASTM E92 | HV0.5, HV1, HV2, HV3, HV5, HV10, HV20, HV30, HV50, HV100 | |

| ROCKWELL TEST PROCEDURES ISO 6508-1, ASTM E18 | A, B, C, D, E, F, G, H, K, L, M, P, R, S, V, 15N, 30N, 45N, 15T, 30T, 45T, 15W, | |

| KNOOP TEST PROCEDURES ISO 4545-1, ASTM E384 | HK0.5, HK1, HK2 | |

| PLASTIC TESTING BALL INDENTATION ISO 2039-1 | HB5: 49N, 132N, 358N, 961N | |

PLASTIC TESTING BALL | HRR, HRL, HRM, HRE | |

| ROCKWELL CARBON TESTING BALL INDENTATION DIN 51917 | HR2.5: 7 HR5: 7, 20, 40, 60, 100, 150 HR10: 20, 40, 60, 100, 150 | |

| BRINELL DEPTH TESTING (NON-STANDARDIZED) HBW-T | HB-T2.5: 6.25, 15.625, 31.25, 62.5, 187.5 HB-T5: 25, 62.5, 125, 250, 750* HB-T10: 100, 250, 500* | |

| PC | External standalone PC with 24 monitor or 19,5 touch monitor | |

| MACHINE CONTROL | DiaMet software | |

| Z SPINDLE | Manual hand wheel and automatic Z axis drive | |

| CLAMPING DEVICE (OPTIONAL) | Unique clamping fork to fix the sample for testing, can be switched on and off | |

| POSITIONING LASER (OPTIONAL) | Cross target, class 1, 650nm | |

| RING LIGHT (OPTIONAL) | For 2.5x objective, simplifies soft Brinell measurements | |

| MAXIMUM SPECIMEN HEIGHT | 300 mm [11.8 in] | |

| MAXIMUM SPECIMEN WEIGHT | 70 kg [154 lb] | |

| DEPTH FROM CENTER LINE | 274 mm [10.7 in] | |

| TEST STAGE DIMENSIONS | T-slot stage with 12mm slot width, 300mm [11.8in] x 400mm [15.7in] | |

| OPERATING TEMPERATURE RANGE | 10 to 38C [50 to 100F] | |

| HUMIDITY | 10% — 80% non-condensing | |

| MACHINE DIMENSIONS (L W H) | 704 mm [28 in] 534 mm [21 in] 995 mm [39.2 in] | |

| ACCESSORY | All anvils with 25mm pin | |

| MACHINE NET WEIGHT | Ca. 300 kg [660 lb] | |

| POWER SUPPLY | 110 — 240V / 50 — 60Hz |