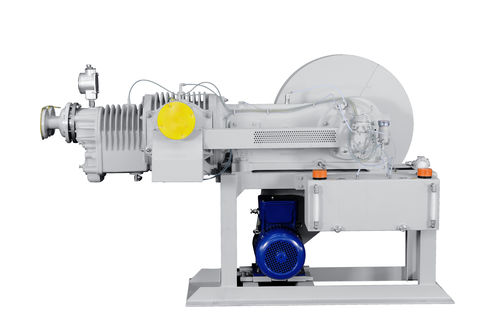

A sump pump designed to EN 733 (DIN 24255), ISO 5199 — ISO 2858 / EN 22858, API 610 / API 682. Standardized and modular design Magnetic driven option Customized sump depths up to 10 m Re-producible optimized hydraulics High efficiency impeller Closed impeller with back vanes providing axial balancing of impeller loads Half open impeller with wear plate and external adjustment Oil seal standard shaft sealing. Gas tightening option by mechanical seal or Gland Packing Discharge flange according to ISO 7005 PN16, PN20, PN50 or ANSI B16.5 150 lbs, 300 lbs Atex certification Pumped liquid lubricated silicon carbide radial bearings External lubrication optional Heavy duty grease lubricated double row angular contact bearing for axial loads Standard IEC flange motor Mounting plate vapor tight or pressurized design Rectangular or circular mounting plate API 610 / API 682 execution engineered for hydrocarbon and petrochemical processing industries Suitable for Thin, clean or slightly contaminated liquids such as water, effluent, cleaning products, chemicals, hydrocarbons

Технические характеристики

CharacteristicsFluidwater, oil, greaseOperationelectricTechnologyimpellerMobilitystationaryDomainindustrialApplicationsdischarge, cleaning, lubrication, sump, tighteningProtection levelstandard, ATEXOther characteristicsmechanical, standard, double, flange, modular, axial, lubricated, radial, open, sealFlow

1,500 m³/h (52,972.00008 ft³/h)

Pressure

16 bar, 35 bar (232.06 psi)

Head

160 m (52411)

Fluid temperature

160 °C (320 °F)