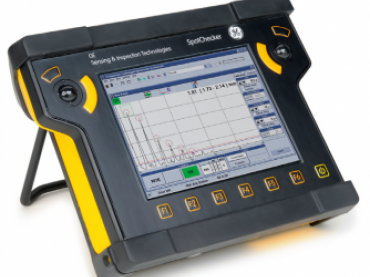

Product Information

A wide range of applications

The USM Go+ has been designed to provide flaw detection capability in inspection situations throughout the industrial and process spectrum, from aerospace to power generation and from the automotive sector to the oil and gas industry.

Weld Inspection:

• Trigonometric projections with curvature correction.

• AWS D1.1 sizing

• DAC/TCG

• DGS

• Color Leg

Inspection of Forgings and Castings:

• Manual PRF adjustment

• Phantom echo indicator

• DGS

• Backwall Echo Attenuator (BEA)

Inspection of rails:

• High PRF (up to 2000 Hz)

• Lightweight: 850 g (1.87 lb.)

• Small size and ergonomics

Inspection of Composites:

• RF Display

• 2 gates with B-start triggered with echo in gate A

• TCG correction with high slope 120 dB/μs

• Reflector depth indicated in layer

For more demanding applications:

• Narrow band filters

• Low noise digital amplifier

• Square wave pulser

Contact us for information on how to upgrade your USM Go+ Instrument to include a full DMS Go+ A-Scan Thickness Gauge just by updating the software!

The DMS Go+ series A-scan thickness gauge uses the same operating platform and hardware as the state-of-the-art USM Go+ portable flaw detector. This offers the ability to have an A-scan thickness gauge and full-fledged flaw detector in one powerful & flexible instrument.

Learn more about DMS Go+ A-Scan Thickness Gauge