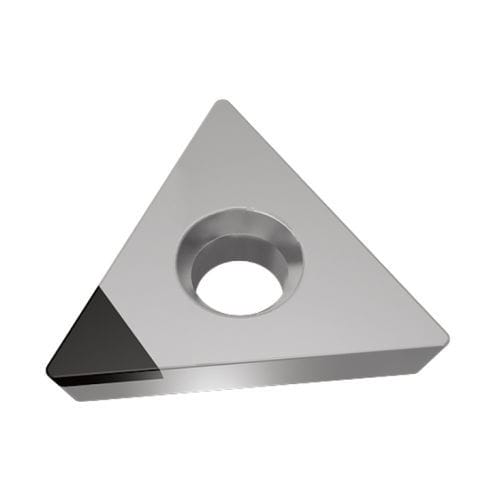

As a high feed milling cutter, the MultiEdge 2Feed mini is used particularly for roughing small and medium-sized components. With a carrier program in diameters of 16-42mm as a screw-on milling cutter with 2-6 indexable inserts, each with 2 usable cutting edges, as well as in diameters of 35-80mm as a arbor type milling cutter with up to 9 indexable inserts, the MultiEdge 2Feed mini can play out its strengths particularly well — and thus guarantees top performance. With high-performance coated cutting grades, the MultiEdge 2Feed mini is suitable for numerous applications in dry and wet milling of steel, cast steel and cast iron, stainless and rust-resistant steels, alloyed and unalloyed steels and high tensile materials. A uniform indexable insert for the entire diameter range enables particularly flexible use. The positive cutting geometry makes high feed milling with the MultiEdge 2Feed mini possible even on low-performance machining centers. Two insert geometries are also available for all versions: While the insert with negative protective chamfer (ER geometry) has a particularly stable cutting edge, the geometry with chip groove (SR geometry) is characterized by a softer cut.

Технические характеристики

CharacteristicsGeometrytangentialConstructionindexable insert, with positive insertTyperoughing, finishingMaterialhigh-speed steelTreated materialfor stainless steel, for hardened steel, for cast iron, for non-ferrous materials, for hardened materialsOther characteristicshigh-performance, with internal coolant, high feed rate, modular, screw-in, for high-speed cuttingDiameter

Max.: 80 mm (3.15 in)

Min.: 16 mm (0.63 in)

Length

28 mm, 50 mm (1.1 in)