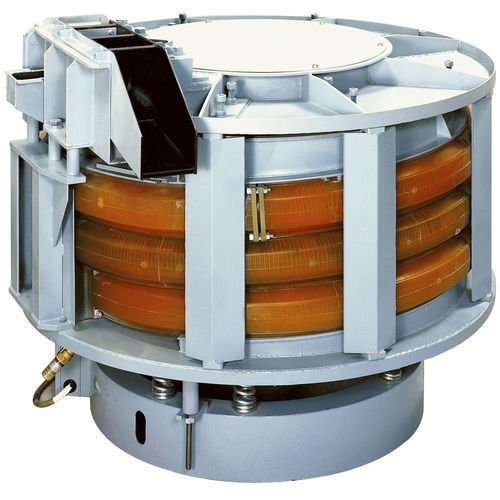

Continuous vibratory finishing available. (Easy to be integrated into production line) This machine has two size as 170L and 450L. *BENEFIT Segmentalized urethane hoses are wound around the vibrating motor and assembled spirally as one hose. Abrasive media should be loaded into the urethane hoses and vibration is given. If workpieces are continuously loaded into urethane hoses from loading port, strong compression force is generated to mass. Mass flow in the urethane hoses finish workpieces within one cycle. Workpieces and abrasive media are separated on the separation screen. Workpieces are unloaded through unloading port while abrasive media return to the hose through separation screen. *APPLICATION Applicable to all Metals, Plastic, Ceramic, Glass and so on for the purpose of Deburring, Descaling, Rough Finishing, Precise Finishing and Luster Finishing.

Технические характеристики

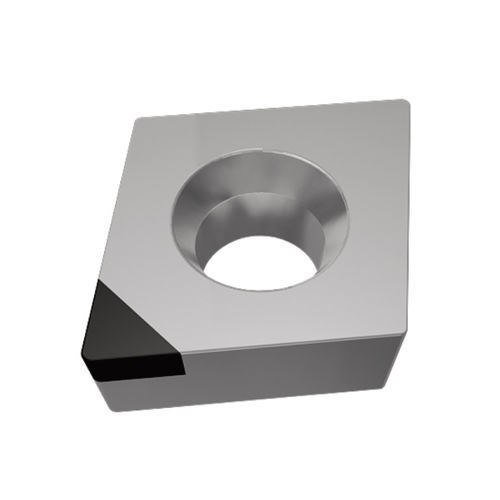

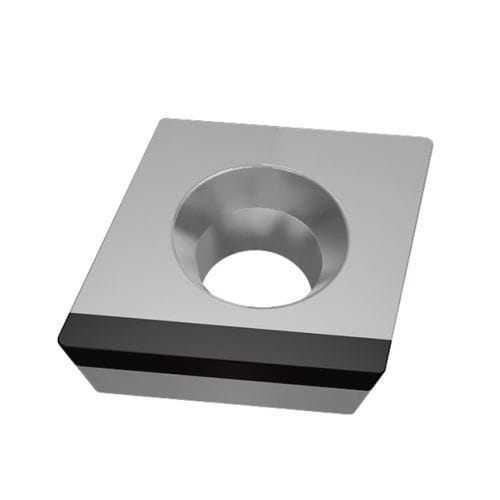

CharacteristicsAssociated functiondeburring, grinding, polishing, finishing, edge rounding, polishingTypestream finishingApplicationsindustrial, for tools, for bars, for micro-finishing applications, for tubesTreated materialmetal, for composites, steel, for stainless steelOther characteristicssemi-automatic, continuous, for high-volume production, with sieving systemsPower

Max.: 11 kW (14.96 hp)

Min.: 5.5 kW (7.48 hp)