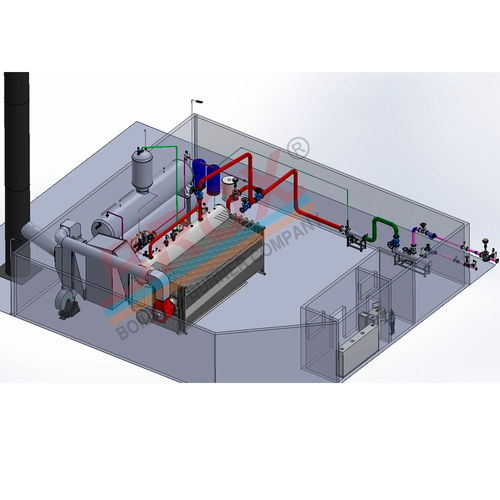

Sheet thickness of Scotch fire-tube and three-pass steam boilers with corrugated furnace commonly used in the world increases when steam and pressure capacity increases. For High pressure and High capacity scotch steam boilers,convenient thicknesses, Body sheet : 30 mm (max) Front-Back and Iner plates : 25 mm (max) Corrugated furnace sheet : 22 mm (max) Furnace Firebox side : 25 mm (max) Back of Furnace firebox : 20 mm (max) For higher capacities, Water tube packet D type steam boiler must be used instead of Scotch steam boilers as required by standards. Water tube boilers can be used as 2 (two) or 3 (three) pass and with economizer and If requested, with superheater. Water tube steam boilers had been used for the first time in small, medium and large-sized businesses in our country by importing in 1940s and have been used since 1966 until today as home production. Steam drum (top drum), Water drum (bottom drum), combustion chamber, front and back wall pipes, combustion chamber and left side wall pipes, finned pipes or by making water walls as fin are packed. Water tube steam boiler can be manufactured with higher steam capacity and pressure beside Scotch Steam Boiler. As 40-45 kg/m2.h steam is generated by scotch steam boilers, Water tube packed steam boilers have the ability to generate 45-55 kg/m2.h.

Технические характеристики

CharacteristicsProductsteamPower sourcefuel oil, natural gas, solid fuelFireboxwater tubeOther characteristicslow-pressure, high-pressure, industrial, high-temperaturePower

Min.: 12,000 kW

Max.: 105,000 kW

Steam production

Min.: 18,000 kg/h (39,683.21 lb/h)

Max.: 150,000 kg/h (330,693.39 lb/h)

Pressure

Min.: 6 bar (87.02 psi)

Max.: 80 bar (1,160.3 psi)