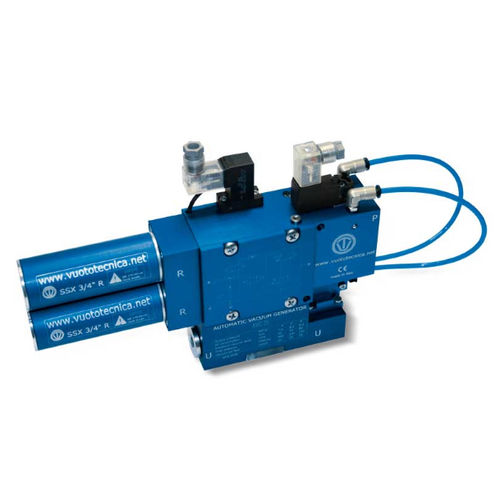

These generators are independent vacuum units capable of driving a vacuum gripping system They have been specially designed for the AUTOMOTIVE sector and they are equipped with single ejectors that, given the same flow rate as the multi-ejector generators, allow for a quicker grip. They are provided as standard with a built-in pneumatic energy-saving device. They are composed of an anodised aluminium mono-block structure, inside of which are installed the ejectors, the servo-controlled slide valve for the compressed air supply and are contained the vacuum chambers as well as the various connections. The following are instead installed on the outside: — A bistable impulse solenoid valve for controlling the slide valve. — A solenoid valve for blowing the ejected compressed air. — A flow regulator for dosing the ejected compressed air. — Two silencers for removing noise from the ejected air. — An aluminium manifold provided with vacuum connections with built-in: • A pneumatic vacuum switch for managing the compressed air supply according to the set level of vacuum (energy saving). • A check valve for maintaining the vacuum in case of electricity or compressed air failure. • A suction filter, easy to inspect through the transparent polycarbonate lid.

Технические характеристики

CharacteristicsNumber of stagessingle-stageApplicationsfor automobilesUltimate vacuum

Min.: -85,000 Pa (-12.33 psi)

Max.: -60,000 Pa (-8.7 psi)

Flow rate

Min.: 16.5 m³/h (582.69 ft³/h)

Max.: 25.2 m³/h (889.93 ft³/h)