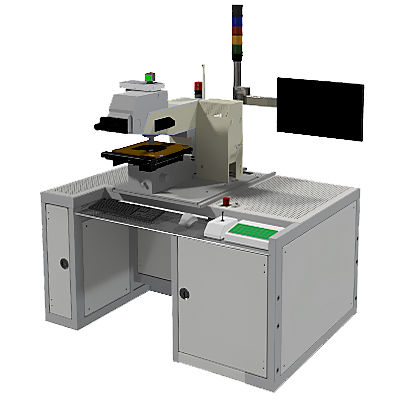

Special testing machines for strip tensile tests, friction tests and draw-bead tests on deep drawn sheets in the automotive industry Sheet metal forming test methods provide characteristic values for metal processing. One sheet metal forming process is deep drawing. In the automotive industry, the demands on the properties of sheet metal are constantly increasing: these include, for example, high stability with simultaneous formability and the lightest possible weight. These special testing machines can be used to determine the abrasion and friction properties of deep-drawn sheets. Such sheets are used, for example, for engine hoods, fenders, doors or pillars. Automobile manufacturers produce body parts like these by automated deep drawing. Possible types of tests: — Tensile tests on the strip — Friction tests — Tribological tests — Draw-bead tests General features: — Regulation of the tensile load and test speed — Regulation and recording of the holding force — Control of specimen temperature regulation in the grips and optionally separate specimen pre-temperature regulation below the grips

Технические характеристики

CharacteristicsTest typetensile, tension, frictionOperating modeautomatedTest materialfor sheet metalSectorfor research and development, for the automotive industry, for the aerospace industry, for quality control, for the aeronautical industryTechnologyelectromechanical, strain gaugeConfigurationverticalOther characteristicshigh-acceleration, coating plasticity, with data logger