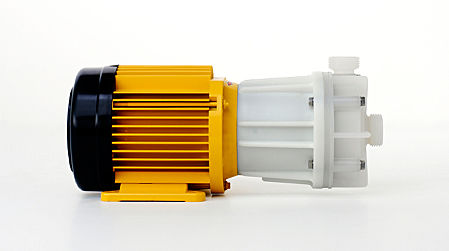

In the U Pump Series, the motor power is transmitted without slip directly to the pump impeller with a rigid shaft (no magnetic coupling). A mechanical seal prevents the leakage of the media to be pumped and ensures the leak proof sealing of the centrifugal pump. Advantages of the U Pump Series: also applicable for higher viscosities or metallic particles in the medium the highest chemical resistance robust, thick-walled design low-maintenance through an optimal adaptation to the medium to be pumped long-lasting and wear resistant, various types of designs for almost all operating conditions open impeller (i.e. solids up to 3 mm grain size and 10 Vol. % possible) models are also available, where no metal parts are in contact with the medium easy to maintain (wear parts and the mechanical seal can be changed swiftly) universally applicable, quiet and compact various chemical resistant materials can be supplied as stock items available as explosion proof version for combustible environments (ATEX) The U Pump Series is universally applicable. The design and manufacturing materials allow for optimization for many operating conditions and media to be pumped. This results in application possibilities, amongst others, for the following application fields Wastewater treatment Filtration Exhaust air scrubbers Electro-plating technology Environment engineering Textile industry Laboratory applications Photographic chemicals Purifying plants Applications also for dirty and metallically contaminated media Outer side set up with fluctuating viscosities

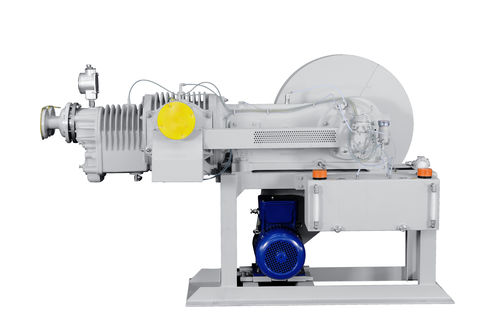

Технические характеристики

CharacteristicsFluidfor seawater, for chemicalsOperationwith electric motorTechnologycentrifugalDomainchemical, for wastewater treatment, for the textile industryProtection levelATEX, explosion-proof, explosion-proof, chemical-resistantOther characteristicssealFlow

500 l/min (132.08603 us gal/min)

Head

40 m (13102)

Power

Max.: 5.5 kW (7.48 hp)

Min.: 0.18 kW (0.24 hp)