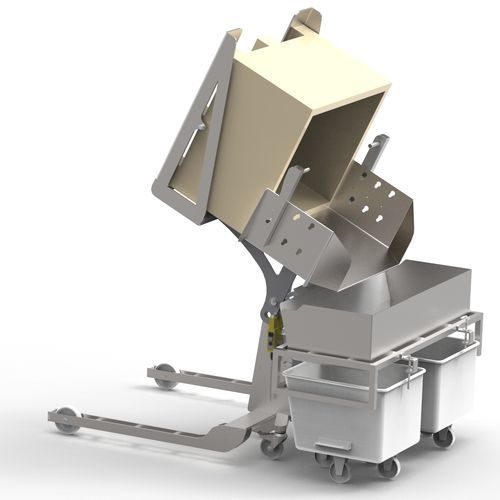

The rotary arm wrapping machines is used to wrap stretch film around a loaded pallet. Film provides extra support while the products are being transported and storaged. The machine is reliable and good partner. It can run in a tough condition and take hard wrapping for long hours. Additionally , wrapped loads is easy, convenient and safe. Food industry, chemical industiry and steel industry are available. Control • PLC and touch screen • Feed and cut flim automatically. • Measure packing height automatically by sensor. • Layer amd wrapped zone of the load can be set. • Identify the load by sensor. • You can set intensive flim wrapping layer. • Film Tension can be adjusted. • The turntable speed is availble in 3-12rpm. • Film carriage moves up and down speed • Cycle break capability • Single start, reset and emergency stop buttons • Turntable jog button • Wrapping position can be reset. • Speed of conveyor is adjustable. Rotary arm • Align turntable position. • Soft start and soft stop. Film carriage • Prestretch ratio can be specially made according to your requirements. • The power of pre-stretch system can be up to 200% to min film consumption. • Film carriage is driven by separate DC Motor. • The carriage door opens and closes easily and flexible • The turntable with double-chain makes move quietly and safely. FHOPE-RAS200 is available also with integrated top sheet dispenser TS for dust/water proof covering of palletized loads. The top sheet cover device integrated onto the machine allows automatic positioning of the polyethylene sheet over the load during the wrapping cycle.

Технические характеристики

CharacteristicsTyperotary armOperating modeautomaticProduct applicationspallet, for chemical products, for the food industryOther characteristicsstretch filmHeight

2,000 mm (79 in)

Width

1,200 mm (47 in)

Length

1,200 mm (47 in)

Rotational speed

Max.: 12 rpm (75 rad.min-1)

Min.: 3 rpm (19 rad.min-1)