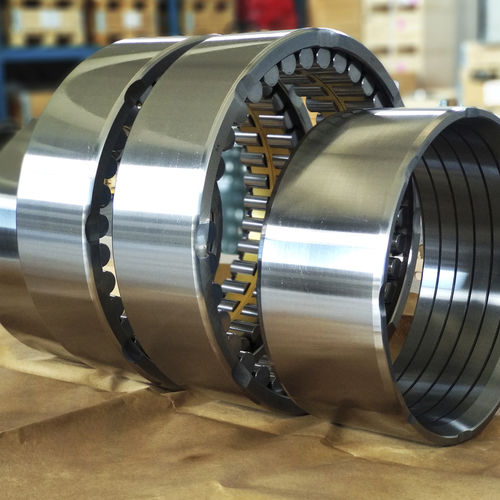

Bearings intended for use in steel mills are subject to extreme temperatures, contamination and operation at very different speeds. Thanks to the knowledge gained through a significant engagement in the field, we are able to best produce bearings for rolling mills roll necks and design and produce standard and special bearings for various applications related to steel machining. TECHNICAL SPECIFICATIONS Available alternatives Four rows radial cylindrical roller bearings, medium and big dimensions, angular contact ball bearing, tapered roller thrust bearings, two rows. Dimensional accuracy P0….P5 (according to DIN 620) Running accuracy P0….P4 (according to DIN 620) Preload and standard radial clearance according to tables and drawings (except particular customer requests) Material of the rings 100Cr6 (UNI 3097 – WNr. 1.3505) / 100CrMo7 (UNI 3097 – WNr. 1.3537) / 20CrMo / 20CrMnTi Surface hardness 58 / 64 HRc

Технические характеристики

CharacteristicsRolling elementcylindrical roller, tapered rollerConfigurationradial, angular-contact, four-row, multi-rowMaterialcarbon steelOther characteristicswith brass cage, high-temperature, custom, large, heavy-duty, high-quality, inch-size, metric-sizeApplicationsfor industry, for rolling mills