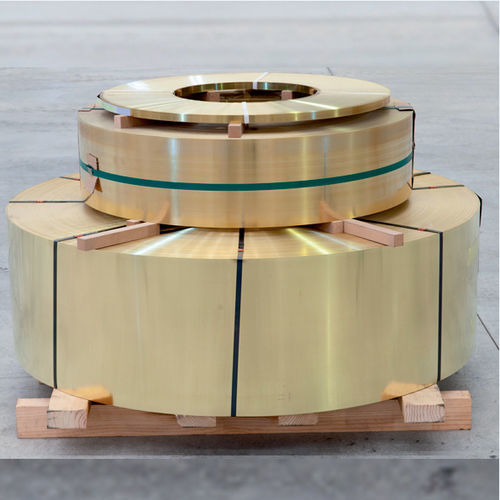

Brass strip CuZn15: CuZn15-R260 CuZn15-H055 CuZn15-R300 CuZn15-H085 CuZn15-R350 CuZn15-H105 CuZn15-R410 CuZn15-H125 CuZn15-R480 CuZn15-H150 CuZn15-R550 CuZn15-H170 BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Type of coating: Electrolytic s/EN14436 and Hot dip s/EN13148 * The data contained in this website are mere information and do not constitute, in any case, contractual conditions of supply. Except for error or omission.

Технические характеристики

CharacteristicsShaperibbonThickness

Max.: 6 mm (0.236 in)

Min.: 0.05 mm (0.002 in)

Length

5,000 mm (196.85 in)

Width

Max.: 1,250 mm (49.21 in)

Min.: 3 mm (0.12 in)