In recent years, a new generation of coatings has developed strongly, with considerable commercial success. These Diamond-Like Carbon (DLC) coatings present the advantage of possessing high hardness (1,500 -3,200 HV) but also a coefficient of friction much lower than that of conventional hard layers such as TiN, TiCN, etc. (5 to 10 times lower). This unique combination of properties has opened up new possibilities, permitting the improvement of technical parts like engine components, etc. Moreover, these coatings are generally bio- compatible and therefore suitable for food contact and medical applications. So as to meet the various operating conditions encountered by technical components used for automotive and other generic industrial applications, HEF has developed a range of DLC coatings capable of meeting all friction reduction requirements. HEF is thus heavily involved in the development of technologies aimed at reducing fuel consumption and CO2 emissions in the automotive industry, the solutions developed by HEF now being used by engine manufacturers worldwide for the improvement of friction: • In rocker arm systems • In mobile coupling systems • In transmission systems These coatings generally comprise several layers of various materials such as Cr, CrN, Si, W and WC- C combined with a top layer of amorphous carbon enriched or not with hydrogen. The selection of the sub-layer is based on several factors such as the adherence requirements, the wear mode, the type of contact, the friction regimes encountered during operation, the load applied and other metallurgical considerations.

Технические характеристики

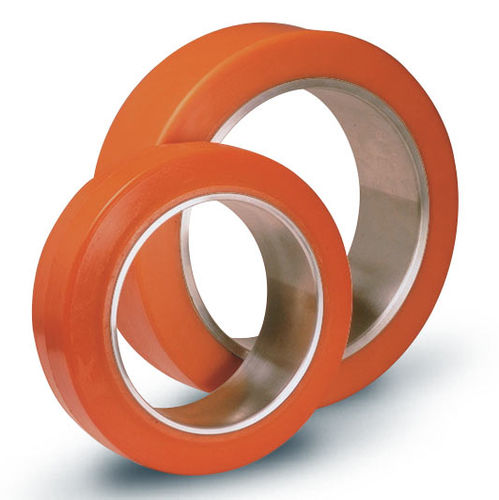

CharacteristicsFunctionprotective, abrasion-resistantMaterialdiamond like carbonDomainfor industrial applications, for the automotive industry