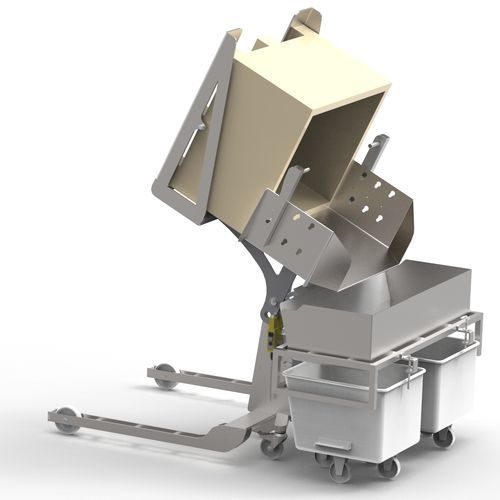

The HS-200 is a flexible and mobile automation system for optics manufacturing. It smoothly loads up to 408 optical workpieces per cycle with a positioning accuracy of +/- 0.1 mm. Its flexible design allows adding washing and turning stations at a later stage, automating even more the production process. Efficient & mobile automated workpiece handling The HS-200 is compatible with most Satisloh´s grinding, centering & polishing machines: SPM/SPS-200, SPM/SPS-125, SPM/SPS-55, PR-150 and C-300. Its design, an easy docking system with different suction cups and clamping options, facilitates and simplifies its use with more than one machine and different optical workpieces. Efficient and flexible Handles lenses Ø 15-80 mm and up to 50 mm lens thickness. Compatible with most Satisloh grinding, centering, and polishing machines. Mobile design allows flexible use where needed. Modular, upgradeable design with optional washing and turning stations and double vacuum suction cup. Use 2 trays for highest productivity and minimized reloading – up to 408 lenses per loading cycle. Fully automated loading with at least 250 mm/sec increases your productivity. Reliable Repeatability of +/- 0.1 mm guarantees smooth operation. Very high lens handling sensitivity for less damage as with manual loading. Easy to use Easy docking system saves installation time. No changeover needed — can remain at machine during manual loading. Capacity — 408 lenses Ø ≤ 18 mm, 2 traysper loading cycle Geometries: — Spheres, aspheres, cylinders, toroids, freeforms, prisms & other optical surfaces Capacity — 408 lenses Ø ≤ 18 mm, 2 trays per loading cycle Geometries: — Spheres, aspheres, cylinders, toroids

Технические характеристики

CharacteristicsOperating modeautomated, modularProduct applicationsworkpiece, for grinding/sanding/polishing machines, optical lens, flexible, mobileApplicationsmobile