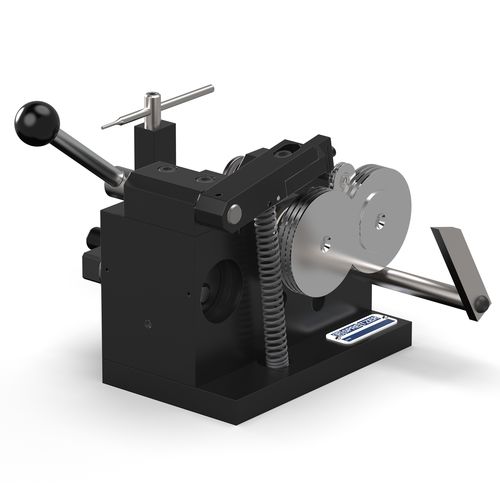

• — Four Column design • — Four Hydraulic Cylinders • — One-touch Operation • — Considerable Clamping Force • — Outstanding Precision • — Good Ergonomics • — Parallelism Measuring Function Why Die Spotting Press • — It allows you to conveniently match all the parts of the mould in more comfortable position. Check and finish the die at one place in more ergonomic position. • — No more dangerous ways (such as cranes and forklift trucks) to handle the molds. • — No more spotting on injection molding machines, which are costly and difficult to access. • — Optimal accessibility and ergonomics by means of swiveling and tilting plates. • — Low operating and maintenance costs. • — High Flexibility. • — Considerable reduction of correction grinding through reproducibility. • — Trials of hydraulic slides, auxiliary cylinders and ejectors can also be done in single operation.

Технические характеристики

CharacteristicsOperationoleodynamicFunctiontest, tryout, die-spottingStructurecolumn type, 4-column, turntable, rotating table, single-sided, with lifting tableControlautomaticOther characteristicscustom, with pressure regulator, repair, extra-high-pressure, for industrial applications, for the automotive industry, for plastics, for automotive parts, for toolsForce

3,500 kN, 4,000 kN, 5,000 kN

Opening

Min.: 400 mm (16 in)

Max.: 3,000 mm (118 in)