Product Information Features and Benefits

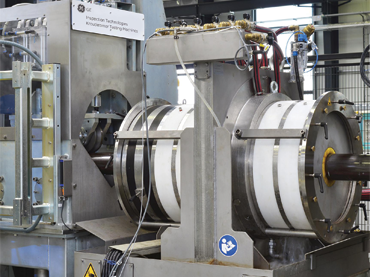

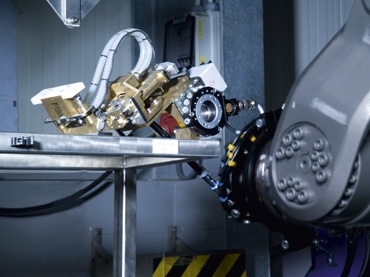

- Modular design: the basic system consists of a tank, a linear motorized mechanical 3-axes subsystem and a prober holder. Optional components, such as turntable, roller, chuck, motorized manipulator, special evaluation software, can be selected and combined to provide a tailor-made solution

- High precision scanning mechatronic devices to ensure motion accuracy

- Optional 6-axes coordinated motion control for automated 3D scanning

- Outstanding ultrasonic testing performance and electromagnetic compatibility

- Multi-channel, multi-batch and multi-task functions to improve inspection efficiencies

- Simple operation with application specific software based on Windows-7 operating system

- Dual monitors with real-time A/B/C-scan display

- Specified software tools to enhance flaw interpretation

Typical applications in the iron & steel, non-ferrous metal, aviation and automotive industry such as:

- Rod: cleanliness test of bearing steels (as per ASTM E588 or SEP1927)

- Ring: internal defects testing of bearing rings

- Plate: internal defects and bonding area inspection of sputtering targets