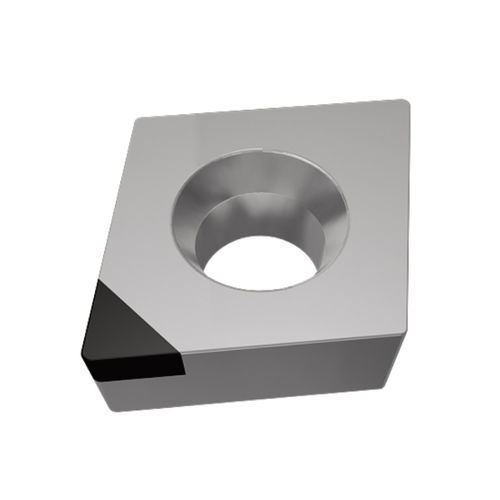

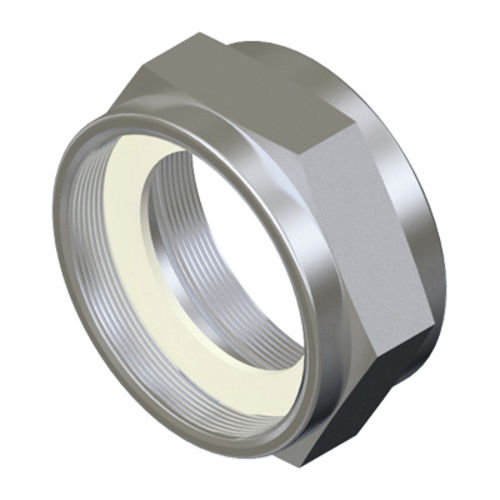

The machine tap consists of cobalt alloyed heavy-duty high-speed steel. Its high heat resistance means a longer tool life. For through threads and bottoming threads in unalloyed and alloyed steels up to a strength of 1000 N/mm², malleable cast iron and non-ferrous metals. The thread is cut in one operation. Like high speed steel with cobalt alloy. This heat-resistant material is used for processing materials with high strength and in long cutting channels with correspondingly strong heating. The cobalt content of 5% provides a higher heat resistance and higher stressing capacity. Schematic illustration. Smaller diameters can be supplied with a tip for production reasons. Nominal thread size Rp Rp 3/8′ Net weight 0.06 kg Length 100.0 mm Spiral length 22.0 mm Core hole diameter 15.3 mm Shaft diameter 12.00 mm Technical data Coating — uncoated Shaft — Square shank Cutting direction — right hand cutting DIN — DIN 5156 Flank angle — 55° Nominal thread size Rp — Rp 3/8′ Form — type B, 4 — 5 threads with progressive tap

Технические характеристики

CharacteristicsTypemonoblocMaterialHSS-EMaterials to be tappedfor steel, for cast iron, for aluminum, for brass