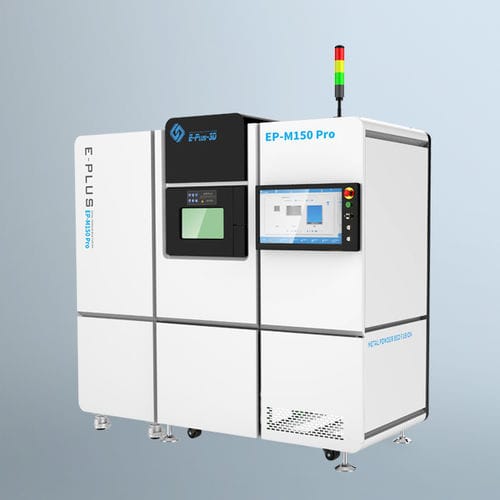

EP-M150Pro Metal 3D Printer EP-M150Pro adopts patented MPBF™(Metal Powder Bed Fusion)to produce high performance, high accuracy and high details parts at large scale. The machine is capable of optional single/dual laser system, and 200/500W laser source for different production requirements. The available materials are Aluminum alloy, Titanium alloy, Inconel alloy, Maraging steel, Stainless steel, CoCr, Copper alloy and so on. High Precision • — High laser beam quality • — Tiny laser spot • — High consistency and uniform laser beam quality from different positons in the building platform High Performance • — The density of printed parts can reach nearly 100 % • — Volatility of mechanical properties< 5 % • — In dual laser printing mode, precision deviation in alignment area ≤ 0.15 mm High efficiency • — The Layer thickness can be up to 100 μm • — With the latested upgrated technology combining dual-laser with large layer thickness mode, the productivity has been risen for 2.3 ~ 2.7 times. Openness • — High consistency, different machines could use the same set of process parameters. • — Machine compatible with multiple materials, the same machine can print multiple materials without adjusting the optical path. User friendly Operation System • — Ergonomics overall design for users • — With ‘one-click printing’ function, each process is ready to run, click the ‘print’ button on the screen to start printing. • — The replacement of filter element, residual material tank substrate and recoater can be completed within 2 minutes

Технические характеристики

CharacteristicsMaterials to be printedmetalTechnologypowder bed fusionApplicationsfor mold manufacturing, prototyping, medicalOther characteristicshigh-performanceX travel

150 mm (6 in)

Y travel

150 mm (6 in)

Z travel

240 mm (9 in)