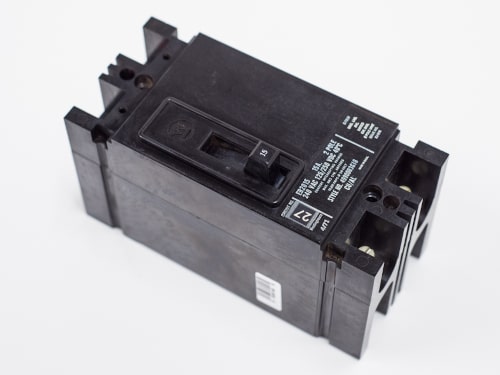

Scope of application: The classical, universal clamp, for vertical 3 axis machining centres Conventional clamping & grip clamping possible Clamping of raw parts, burn and saw cuts by penetrating hardened and interchangeable grip elements into the workpiece Customer advantages: Free of charge introduction to grip technology in comparison to conventional clamping (LC) Existing step jaw systems of product series LC/TC/Titan 125 can be used First and second clamping stations without retrofitting the step jaws Clamping of raw parts such as burn & saw cuts (materials up to approx. 1000N/mm2) through screwable clamping applications (first clamping station) Parallel clamping to machined workpieces with the step jaws (2. clamping station) Upgrade to full clamping function with optional clamping jaws

Технические характеристики

CharacteristicsApplicationsfor machine toolsConfigurationverticalMax. clamping force

40 kN