Scope of application: Can be applied horizontally or vertically – therefore suitable for vertical and horizontal CNC milling machines Conventional clamping, gripper clamping or pull-down clamping are all possible Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely and economically. Product features: High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models The TITAN 2 M is ground an polisched on all sides High-pressure spindle with power intensification. Clamping force does not slacken Enlarged clamping span for secure clamping of unmachined parts Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER Clamping near to neutral axes Clamping jaws of forerunner are compatible Clamping with torque wrench – max. 30 Nm. This makes it possible to work above the table with an unfavour able clamping arrangement on the tool

Технические характеристики

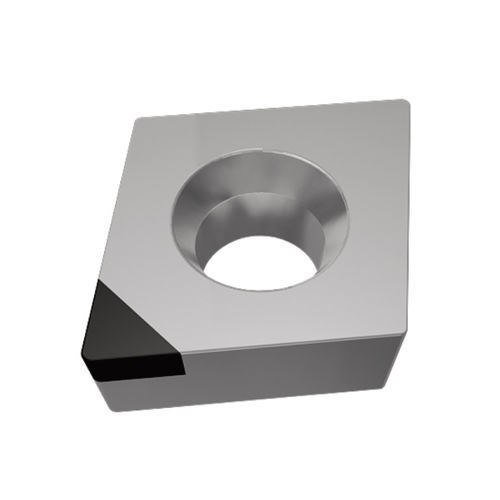

CharacteristicsApplicationsfor machine toolsConfigurationverticalOther characteristicshigh-pressureMax. clamping force

40 kN