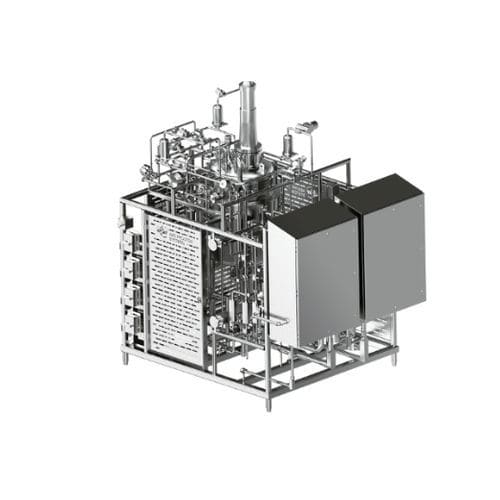

Our READYGo Bioreactor delivers an easily configurable platform that is optimized for cultivated meat. Ranging in volume from 20 to 20,000 liters, it’s flexibility allows companies to rapidly expand their production as their business expands from the start-up phase through full-scale production. The unit is designed for easy integration with our media preparation, harvest/ hold, and CIP/ SIP systems as well as our protein preparation and packaging lines, allowing the quick implementation to configure the unit, and minimizing the time-to-market. Features & Benefits Scalability – Ranging in volume from 20 to 20,000 liters,the READYGo Bioreactor offers a flexible and scalable platform for cultured meat companies to launch products from pilot to full-scale production. Lead-time – Manufactured with “best in class”, non-proprietary components, the READYGo Bioreactor is designed to minimize the time-to-market for scaling up facilities without compromising a customer’s ability to implement their unique process requirements. Capital Expense – Designed to reduce the historically high cost of capital expense associated with cell culture bioreactors, the READYGo Bioreactor meets the necessary needs of the food market without unnecessary added expense. A Leader in Cultivated Meats Our Alternative and Cultivated Meat Solutions can help you tap into this growing market. We are the industry leader in traditional protein processing equipment, and all our machines and systems can be used with equal effectiveness to process alternative and cultivated meats. With the addition of the READYGo Bioreactor, we are equipped to assist companies rapidly scale production.

Технические характеристики

CharacteristicsApplicationsprocess, laboratory, for the pharmaceutical industry, for cultivated meat, for tissue growthOther characteristicsSIP