Product Information Features and Benefits

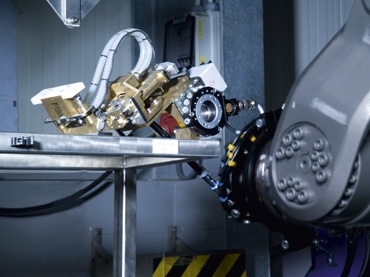

- Electronics and mechanics designed to cover the entire diameter range

- Rapid adaption to new diameters just by exchanging centering devices (3 parts in total)

- Motorized motion (closed control circuits) in linear direction and for probe holder rotation

- Signal connection through slip ring to allow continuous rotation of the probe holder and to reduce the inspection time

- Quick pluggable cable connections between trolley and inspection mechanics

- Light design of inspection mechanics that can be handled “just by one person” with no need for lifting

- Closed loop for oil coupling to minimize oil loss during the inspection

- Full post-processing possibilities and signal display: A-scan and of

- Endless rotation of the probe holder, oil coupling closed loop system, modular push/pull U-profile to inspect the whole axle length just from one side

- Speed Rotation: 35 RPM, Linear: 30mm/s max,

- Inspection length 2,4 m typical with connectable U-profiles, extensions available

- Inspection time 15 min typical, depending on UT setup

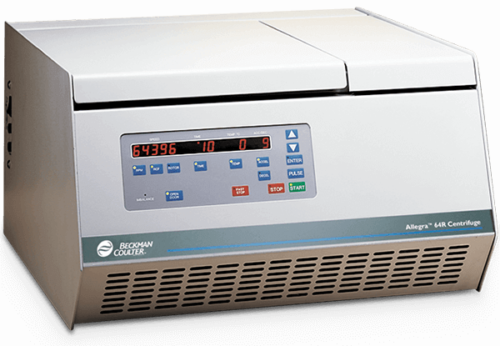

- Trolley Moveable trolley carrying PC (notebook equipped with own battery), UT-Instrument, PLC, oil tank with pumps and storage space for inspection mechanics and U-profiles

- Weight Inspection mechanics approx. 10 kg plus trolley approx. 90kg (without Oil, UPS, main power cable)

- Electric 220-240V ~50Hz, 15 m mains cable at trolley