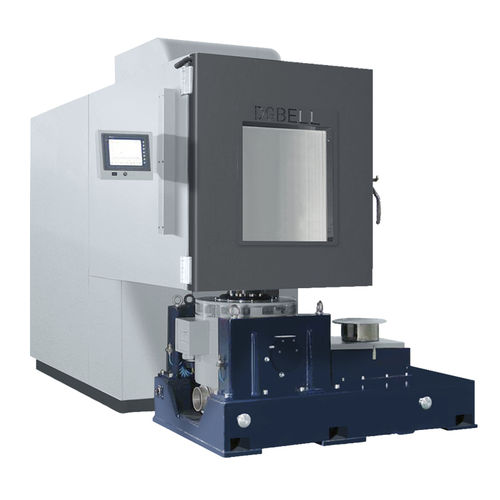

The Temperature Humidity Vibration Combined Test Chamber meets national standards and meets specific testing requirements. It is widely used in electrical and electronic products, automotive parts, materials, etc. through a combination of high and low temperature, low temperature, temperature change, impact, wet heat vibration and other environmental reliability tests. Features • With high precision perfect external design, external with double sides cold-rolled plate electrostatic powder-coated material, internal with SUS#304 high temperature resistant stainless steel. • Insulation material adopts fire resistant high strength PU polyurethane foaming thermal insulating material. • More than 20% of energy saving is achieved &thanks to the introduction of Japan & German advanced refrigerator control technology. • Control system and control circuit components all introduced with famous brands. Standard Compliance • IEC 68-2-1 (GB2423.1-2008) • IEC 68-2-2 (GB2423.2-2008) • IEC 68-2-3 (GB2423.3-2006) • IEC 68-2-30 (GB2423.4-2008) • IEC 68-2-14 (GB2423.22-2008) • MIL-STD-810D (GJB150.3A-2009) • MIL-STD-810D (GJB150.4A-2009) • MIL-STD-810D (GJB150.9A-2009)

Технические характеристики

CharacteristicsTypehumidity and temperature, environmental, vibrationApplicationsfor aircraft, for automobiles, for the aeronautical industry, for electrical equipmentConfigurationfloor-standingOptions and accessoriesstainless steel, with temperature and climatic control, with constant temperature and humidity control, accelerated, with window, low-temperature, for high temperatures, with cyclical temperature/humidity control, for rapid temperature cyclingCapacity

Max.: 1,000 l (264 gal)

Min.: 408 l (108 gal)

Temperature

Max.: 150 °C (302 °F)

Min.: -70 °C (-94 °F)

Length

1,650 mm, 1,750 mm (64.96 in)

Width

850 mm, 1,250 mm (33.5 in)

Depth

1,500 mm, 1,600 mm, 1,800 mm (59 in)