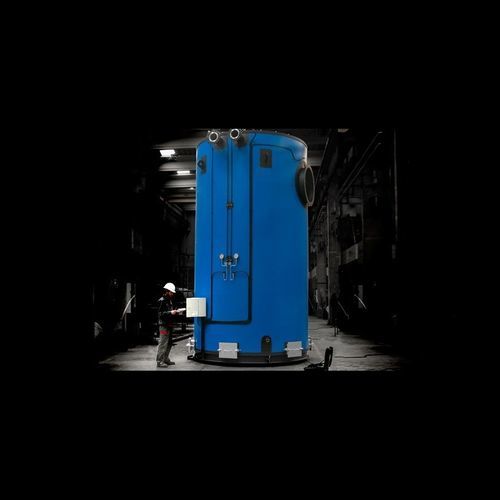

Grinding Resin Wheels Hydraulic Press Production Line Product Characteristics Grinding resin wheels hydraulic press production line included: materials filling hydraulic press, pre-pressing hydraulic press, hot hydraulic press with maximum 2 units, stripping hydraulic press, conveyor system, products storage box, molds cooling device and molds pre-heat device. — Machine Structure: with finite element analysis, which guarantee the strength and rigidity of resin wheels hydraulic press. — Ease Operation: user friendly HMI, ease for setting parameters and recipe storage. — Control System: with PLC & HMI (Siemens brand), which refer to pressing technology requirement and setting parameters on HMI such as pressure, position, hold pressure and multi-pressing. — Operation Mode: each of our grinding wheel hydraulic press equipped with independent hydraulic power pack and electrical system, which to perform four operation mode including: Inching, Manual, Semi-auto and Automatic. — Accuracy Monitoring: equipped advanced linear scale pressure sensor, which can be used in monitoring position and pressure in production, and enhancing the pressing accuracy. — Pressing Accuracy: repeatability of ram pressure achieve to ±3%, control the scrap rate of products caused by machine accuracy. — Energy Saving: using servo motor driving system, fulfill different speed and pressure of requirement. Ensuring the stability of movement with lower noise level. — Heating Control: electrical heating or hot oil heating can be selected. Accuracy of heating temperature control in heating plate within ±4°C.

Технические характеристики

CharacteristicsOperationhydraulicFunctionformingControlautomatic, PLC-controlled, hand-operatedOther characteristicshot, for grinding wheels