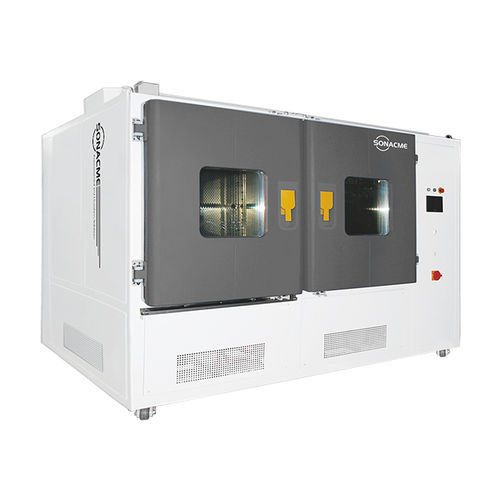

Application Area 1. SONACME Thermal Shock Test Chamber Is Designed To Provide A Rapid Transition Between Hot And Cold Temperature Zones. Provide Vertical, Horizontal And Liquid Models. Thermal Shock Test Chambers Are Used In All Industries, Including Automotive, Electronics, Aerospace And Other Industries, To Help Find Product Defects In Electronic Components And Product Assembly. 2. The Thermal Shock Test Chamber Is Very Important To The MIL-STD 883 Test Standard. With Haoji Technology’s LOW GWP (Global Warming Potential) Technology, Our Test Room Can Provide Up To 40% Energy Saving And R-449A Refrigerant. Structural Features 1. The Inner Chamber Material Is Made Of SUS#304 Stainless Steel With 1.2mm Thickness. Full Welding Structure, Its Sealing Is Very Well And It’s Not Easy To Get Cracked. 2. The External Material Is Made Of Cold-Rolled Plate With 1.5mm Thickness, It Has Gone Through Brushing, Polishing, Painting Treatment, It’s Not Easy To Get Scratched. 3. The Insulation Material Is Made Of Polyurethane Foam With Thicknessof 100mm. 4. The Door Seal Adopts Double Silicon Rubber Sealing Material. 5. The Observation Window Is 4 Layers Of Tempered Glass, The Size You Can Choose By Yourself. 6. In Addition, In Order To Prevent Frosting On The Observation Window When Running Low Temperature, We Setup A Heating Wires Inside To Get It Di-Frosting.

Технические характеристики

CharacteristicsTypethermal shock, cooling, environmental stress screeningApplicationsfor electrical equipment, for automobiles, for materials testing machines, for aircraft, cell, for color assessment, development, for solar panels, for battery, for the aeronautical industry, for auto lamp, for engine, for small parts production, for electronic circuit boards, for wires, device, for windows, thermoplastic pipe, for composite materials, for vehicles, for motors, glass, for sensors, European standards-compliant, for semiconductorsConfigurationcompact, floor-standing, modularLight sourcewhite LEDOptions and accessorieswith window, stainless steel, low-temperature, for high temperatures, with temperature and climatic control, accelerated, for rapid temperature cycling, energy-saving, thermal, for frost resistance testsCapacity

Min.: 50 l (13 gal)

Max.: 500 l (132 gal)

Temperature

Min.: -55 °C (-67 °F)

Max.: 150 °C (302 °F)

Length

Min.: 1,100 mm (43.31 in)

Max.: 1,750 mm (68.9 in)

Width

Min.: 1,930 mm (76 in)

Max.: 2,630 mm (103.5 in)

Depth

Min.: 1,460 mm (57 in)

Max.: 1,980 mm (78 in)