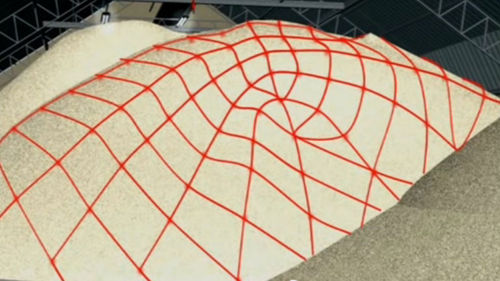

Straight edges, bores, slotted holes and slots are chamfered precisely, quickly and easily. The prism attachment for machining straight edges rounds off the complete package. They are a great helper at a small price. Professional advantages — Ideal for chamfers up to 2mm x 45° — Internal- and external contours can be chamfered and rounded — Dimensional accuracy due to ball bearing guide or guide ruler — No chatter marks — Very good tool life of the solid carbide cutters — Compact handy tabletop unit next to the CNC milling- and turning machine — Precise chamfer adjustment — Speed control for processing different materials — Chamfer angle can be changed due to contour cutter with different point angles — Fast tool change Application — Minimum workpiece thickness 1 mm — Can be used for steel, hardened steel, aluminium, brass, copper, plastics, from soft plastic to acrylic glass, wood and much more — Chamfering or rounding of external and internal contours — Not for permanent use due to crabon-brush motor with duty cycla 50 % / h — Suction only with prism application Options — Prism attachment for straight edges — Guide finger for the use of tapered contour cutters — Extraction device with automatic switch-on (only for KKE 2) Delivery contents — Stop ruler, box wrench 17 mm, union nut, allen key 3 mm, collet ø 6 mm, — Open-ended wrench 14 mm — Insert ring with borehole ø 8 mm -Prism with suction socket, insert ring with borehole ø 12 mm, collet ø 8 mm, allen key 5 mm (only for KKE 2) — Operating manual

Технические характеристики

CharacteristicsOperationelectricTypestationaryApplicationsstraight edges, contourOther characteristicscontourPower

0.6 kW (0.82 hp)

Rotational speed

Max.: 24,000 rpm (150,796.45 rad.min-1)

Min.: 8,000 rpm (50,265.48 rad.min-1)

Chamfer width

Max.: 3 mm (0.1 in)

Chamfer angle

Max.: 90 °

Min.: 0 °