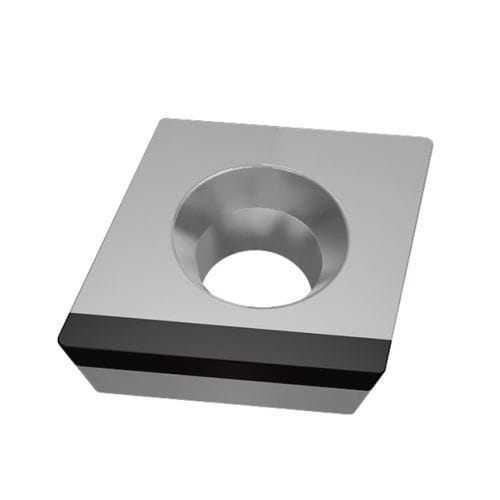

Chipping instead of grinding! As a result of the defined cutting edge geometry, no dust, in contrast to abrasive removal, but chips will occur. This reduces a potential health- and explosion hazard to a absolute minimum in contrary to a grinding process. The safest, most effective and economic solution for manual treatment of aluminium. For processing of aluminium alloys with an angle grinder 115-125mm. The area of application is cross industrial, in container-, vessel and automotive manufacturing, as well as aluminium casting. Most frequent is the pre- and post processing of welding seam (chamfering and trimming), the reaming of root seams as well as rough machining of cast iron parts. Workable materials: Aluminium alloys, copper, zinc, as well as timber and plastics (also fibre -reinforced plastic) — No emerge of dangerous to health and explosive dusts — to be used with an angle grinder Ø 115 and 125 mm — The economic alternative to abrasive roughing- and flapwheels Amounting hole 22,2 mm — Very high material removal rate by simultaneous safe controllability — Thanks to the polished chip guiding surface, no adhesions (buildup cuting edge) — The carbide inserts are extremely durable as wel as reversible-and replaceable — CNC milled from a solid piece of high strength aluminium — Quality tool „Made in Germany“

Технические характеристики

CharacteristicsTreated materialfor aluminum, for copper, for plasticsFunctiongrinding, trimming