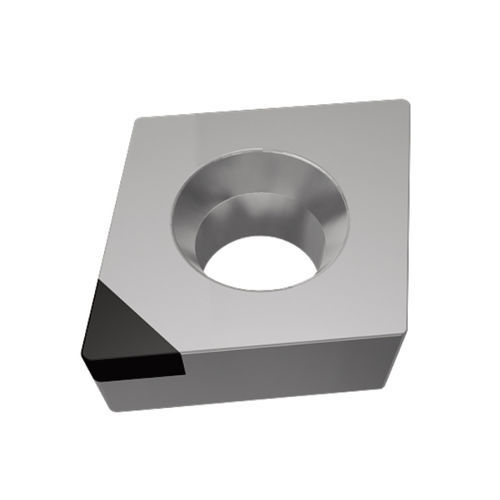

The stationary edge- and contour milling machines are perfect for machining angular and round workpieces with plane inner- and outer contours. They are compact and handy tabletop machines finding their ideal use alongside CNC machines. Professional advantages — Ideal for chamfers up to 1mm x 45° — Suitable for processing small to medium-sized workpieces — Low setup times with maximum flexibility — Excellent chamfers by best spindle accuracy — Zero point clamping — Easy operation — Fast tool change — Speed control (only with Speedy Kontur 270-KSL and Speedy Kontur 320-KSL) — Chamfer angle can be changed due to contour cutter with different point angles Application — For precise deburring and chamfering of inner- and outer edges of flat workpieces — Can be used for steel, hardened steel, aluminum, brass, copper, plastics, from soft plastic to acrylic glass, wood and much more — Suitable for continuous operation Options — Guide finger, radius- and chamfer cutter with guide ball bearing — Attachment prism for processing straight edges — Slug remover-set for face milling of cut-off rotary slugs up to max. Ø1,5mm — Extraction socket — Extraction device with automatic switch-on — Special version for stainless steel processing Delivery contents — Allen key 2.5 mm — Stop ruler — Solid carbide milling cutter Ø6, pointed — Cold-device cable — Insert ring with borehole Ø8mm — Operating manual

Технические характеристики

CharacteristicsOperationelectricTypedeskApplicationsradius milling, contourOther characteristicscontourPower

0.14 kW (0.19 hp)

Rotational speed

Min.: 12,000 rpm (75,398.22 rad.min-1)

Max.: 32,000 rpm (201,061.93 rad.min-1)

Chamfer width

Max.: 2 mm (0.1 in)

Chamfer angle

Min.: 0 °

Max.: 90 °