Product Information

BENEFITS

- Fast & efficient – up to 30 parts/hour (while capturing up to 10 CT slices per part)

- Accurate & repeatable – compliance with MAI Affordable CT Guidelines, demonstrating measurement capability of up to +/- 5% or 0.001 inch

- Data integrity & security – DICONDE workflow and long-term data management

- 2 inspection workflows: 2D radiography imaging and CT slice measurement

- Increased productivity due to high throughput ensuring low inspection time and costs per blade

FEATURES

- 450 kV fan beam inspection and measurement to support throughputs of up to 30 turbine blades per hour with appr. 75 measurement locations distributed over 10 axial positions

- Optimized speed, performance and precision robot-based component manipulation

- Max. sample size up to 190 mm in height and 200 mm Ø, 3D scanning area max. 190 mm x 150 mm Ø

- Up to 2 kg (4.4 lb)

- Unique GE Jupiter line detector array with up to 100 fps scan speed

- Robust design with small footprint for 24/7 operation

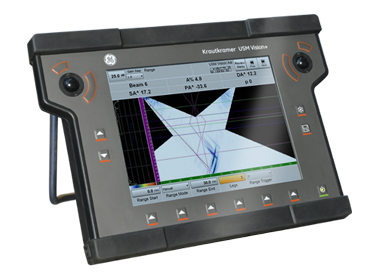

- Integration of GE Rhythm Review software for image viewing, enhancing and archiving based on the standardized DICONDE file format