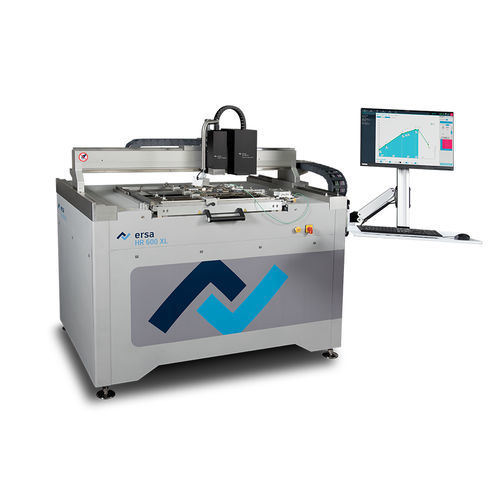

The Ersa Rework System HR 600 XL was developed for large PCB formats — components up to 60 x 60 mm can be processed just as easily as precisely. With the optionally available XL heating head, even components up to 120 x 120 mm edge length can be processed. The Technology of Ersa Rework Systems sustainably secures the added value of electronics: • gentle heating technology • sensor guided soldering processes • contactless residual solder removal • precise component placement • complete process documentation • clear user guidance • Highly efficient 800 W hybrid heating head (optional 2,000 W) • Large-area IR Matrix bottom heater with 25 single heating elements (600 W each) • Process observation with up to 8 thermocouples • Automatic and precise component alignment with the help of machine vision • Highly accurate, motor-driven axis system for component placement (+/- 0.025 mm) • User independent, reproducible repair results • Process control and documentation via the operator software HRSoft 2 • Suitable for the use of the Dip&Print Station • Dimensions (W x D x H) in mm: 2250 x 1700 x 1650 incl. Monitor holder • Footprint: 1691 x 1180 mm • Weight in kg: approx. 312 • Antistatic Design (y/n): yes • Power Rating in W: 16 kW, optional 16 kW + 15 kW • Nominal voltage in V AC: 400, 3 phase, 50/60 Hz, 30 A • Compressed air connection: 6-10 bar (free of oil), 1/4 inch quick bar connect • Volume of air cooling: approx. 110 l/min (@ 6 bar) • Upper heating: Hybrid emitter 60 x 60 mm (0,8 kW), optional up to 150 x 120 mm (2,8 kW)

Технические характеристики

CharacteristicsOperational modeautomatic