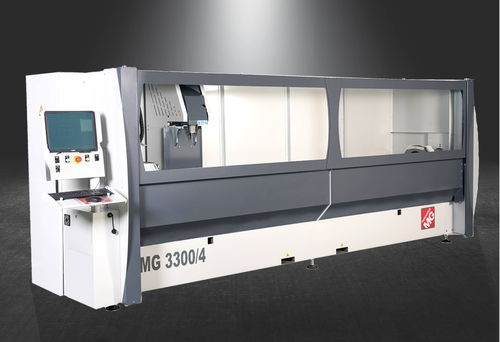

Machining center with moving column and vertical spindle with 4 axis controlled by CNC including rotation of the clamp base which allows any angle ranging from -90 ° to + 90 ° in automatic working cycle. -Motor HITECO of 5,5KW standard -Quick change hand tool cone ISO30 pneumatically controlled, -Automatic tool change with station for 4 tools (optionally 8 tools) -4 pneumatic standard vices with manual positioning ( -Automatic positioning and more vices as option) -Possibility to work aluminum, PVC, steel up to 4 mm and -stainless steel up to 3 mm with a specific accessory. Axis movement and clamps rails with recirculating ballscrew and servodrive Motion rotated clamp base by rail and wheels Numerically controlled axes with 4 brushless motors Transmission axis with tilted teeth rack and pinion Start cycle with two-handed safety device 4 horizontal pneumatic clamps with low pressure device Mist lubrification (emulsified oil) Tool magazine cones ISO30 Vice jaws PVC adjustable using keys Spindle motor driven by inverter Swiveling console USB 2.0 port on the control panel and ethernet RJ45 socket Preinstalled barcode reader connection NC — Industrial PC with Intel microprocessor LCD display — TFT (800 x 600) color 10.4 ‘- touch screen Operating system Windows XP Embedded RT Software- 3D dimensional Indication vice positioning software with reference line of metric

Технические характеристики

CharacteristicsNumber of axes4-axisSpindle orientationverticalStructurecolumn typeMachined materialfor aluminum, for plasticsOther characteristicsmilling, high-speed, high-precision, high-performance, high-productivityX travel

3,300 mm (130 in)

Y travel

250 mm (10 in)

Z travel

200 mm (8 in)

Rotational speed

Min.: 2,000 rpm (12,566 rad.min-1)

Max.: 20,000 rpm (125,664 rad.min-1)

Power

5.5 kW (7.48 hp)