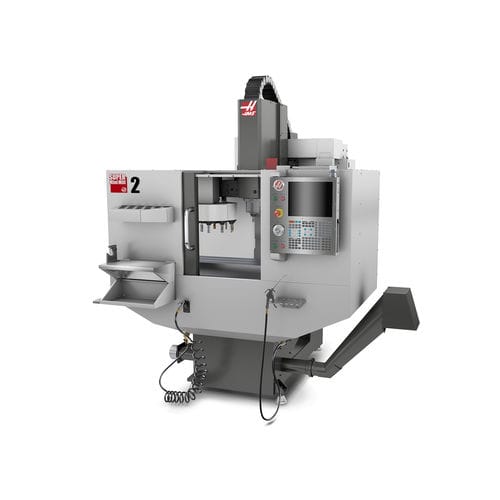

Haas Mini Mills are the industry standard for compact machining centers. They provide an economical solution for small parts machining in a compact package that is loaded with full-size features. The Super Mini Mill 2 is enhanced with a faster spindle and higher rapids for improved production output and part finish. It offers the same combination of small footprint, full CNC capabilities, and affordable price as the standard Mini Mill 2, but with extended travels. It is perfect for schools, start-up shops, or as a first step into CNC machining. It is a valuable addition for shops needing a “second-op” machine, or an additional spindle where space is limited. Enhanced speeds Compact footprint with extended travels Economical solution for small parts Optimal machine for high-volume production Made in the USA

Технические характеристики

CharacteristicsNumber of axes3-axisSpindle orientationverticalSpindle mountBT 40Number of tool stations20 toolsApplicationsfor small parts productionOther characteristicshigh-speed, compact, high-productivity, direct-driveX travel

508 mm (20 in)

Y travel

406 mm (16 in)

Z travel

356 mm (14 in)

Rotational speed

10,000 rpm (62,832 rad.min-1)

Power

11.2 kW (15.23 hp)

Work feed X-axis

30,500 mm/min (20 in/s)

Work feed Y-axis

30,500 mm/min (20 in/s)

Work feed Z-axis

30,500 mm/min (20 in/s)

Table load capacity

227 kg (500 lb)

Tool weight (max)

5.4 kg (11.9 lb)

Tool-changing time

4.2 s

Weight

2,314 kg (5,101.5 lb)